Welcome to IOWA

InOrbit Warehouse Automation (IOWA) is a comprehensive solution for robot operations (RobOps) designed specifically to help warehouse operators deploying smart robots. As the need to drive increased productivity and efficiency in logistics continues to grow in response to supply chain and labor challenges, warehouse automation with autonomous robots allows companies to improve resilience and flexibility in their operations. IOWA can orchestrate all aspects of RobOps in the warehouse, from enabling interoperability to integrating with enterprise systems and fixed infrastructure.

Warehouse Management Integration

Logistics leaders are increasingly adopting autonomous mobile robots (AMRs); however, deployment speed and efficiency are hindered by the need to integrate with existing systems. IOWA works with any robot and reduces the time required to exchange data with the Warehouse Management Systems (WMS), Warehouse Execution Systems (WES) or Enterprise Resource Planning systems (ERP) used to drive operations.

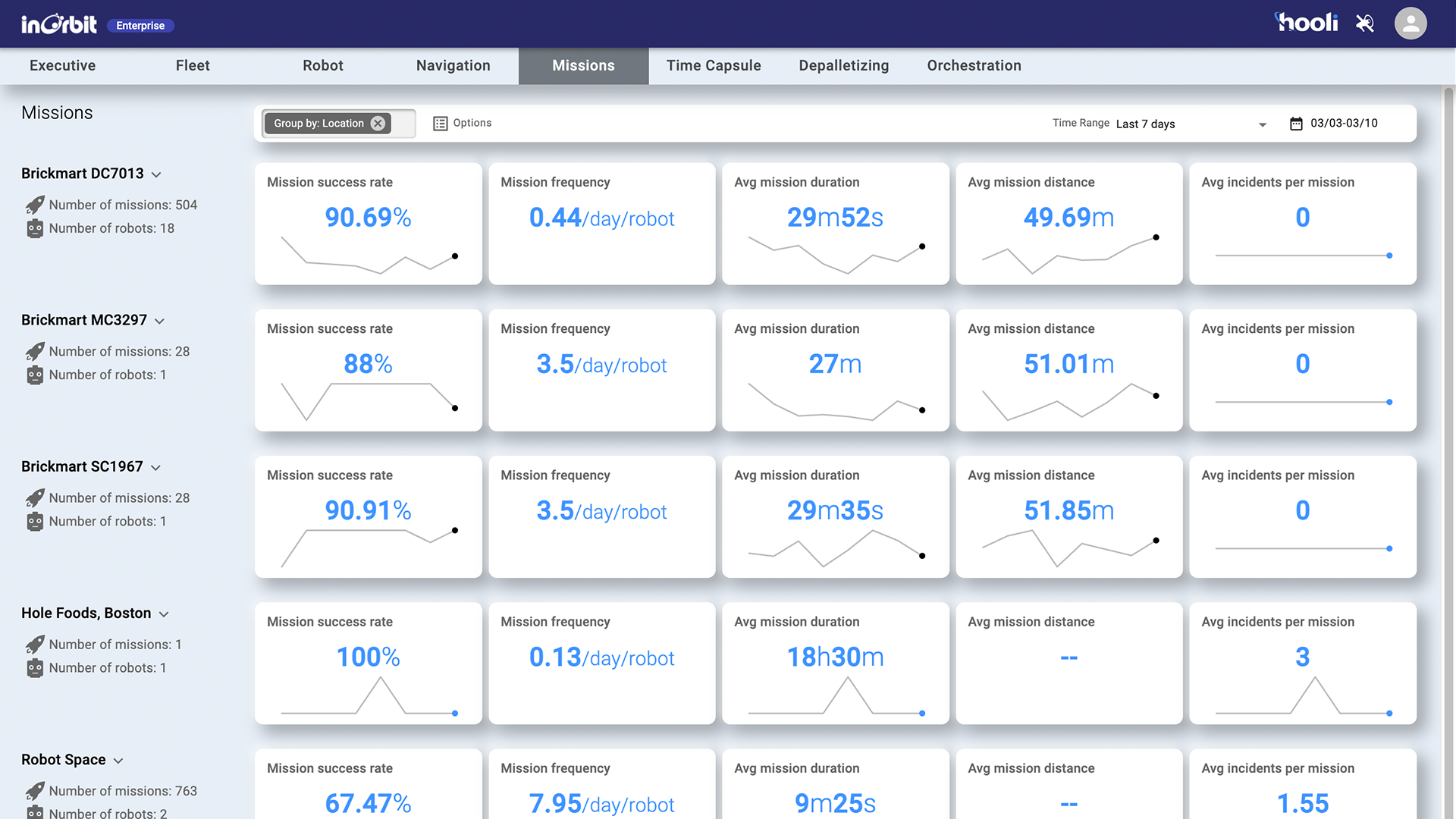

A key component of the InOrbit Warehouse Automation solution is the ability to flexibly define missions for the robots, dispatch robots as part of a workflow and analyze their performance. Missions can be fixed, such as taking a pallet from a palletization cell to a cargo bay, or dynamic, for example, to optimally visit all the pick points required to complete an order. Whether it’s triggering missions in a distribution center or moving material to a production line, interacting with doors and elevators, or sweeping the floor on a fixed schedule, missions drive the behavior of robots in the warehouse.

Single Pane of Glass

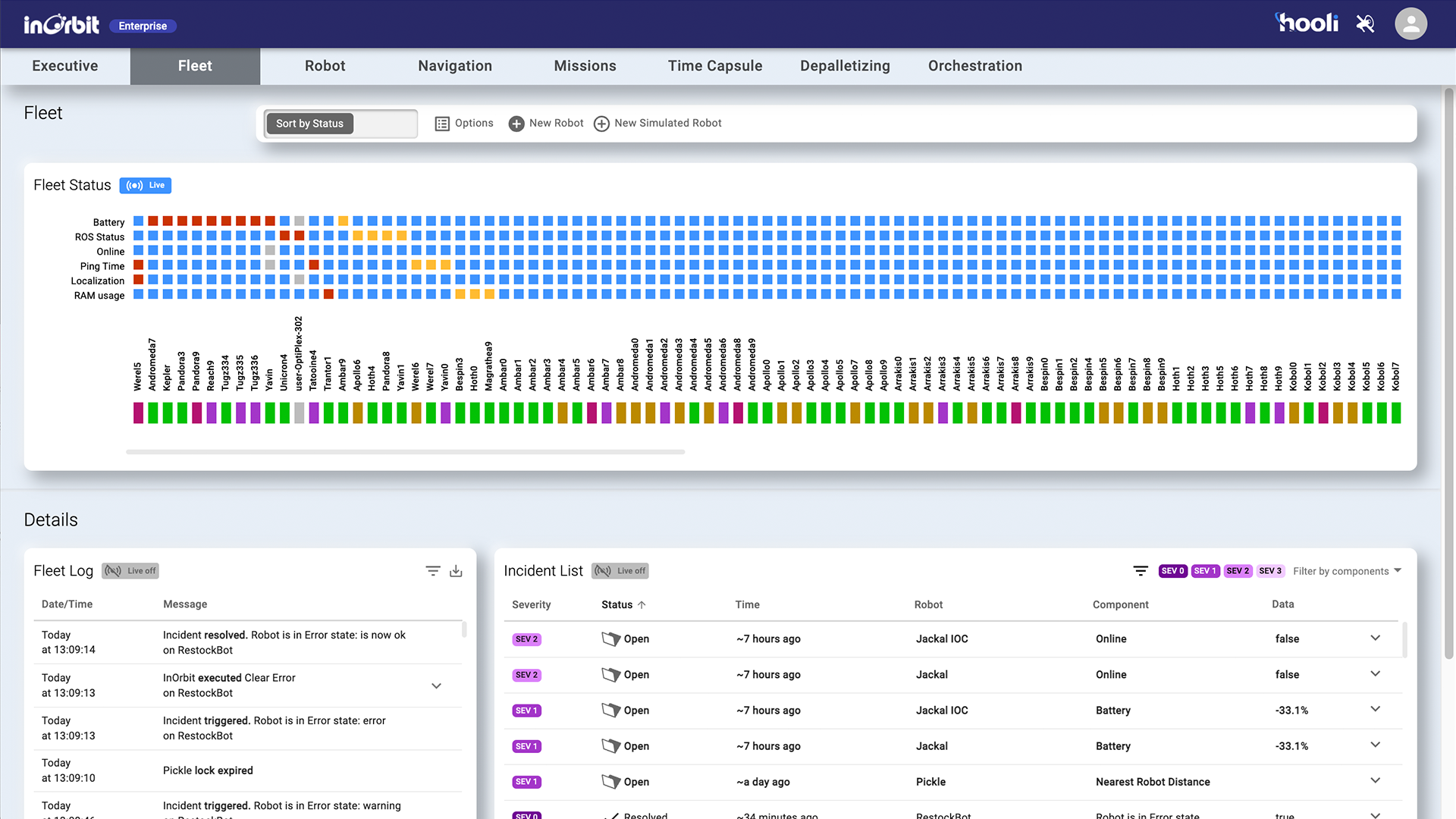

As warehouse automation grows in scope and complexity, the need for access to operational data increases exponentially. Having disparate, disconnected systems limits the ability to optimize operations. With the InOrbit Warehouse Automation solution, enterprise customers can derive insights by consolidating RobOps data on a single platform with configurable dashboards that can be customized for different roles, from a floor operator to a warehouse manager or a central team at headquarters.

Integrating data from various sources, whether on a mobile robot or fixed sensors like cameras and RFID, IOWA enables a complete view of every warehouse. Advanced functionality like custom key performance indicators (KPIs), Configuration as Code (CaC) and Time Capsule™ make InOrbit the leader in RobOps data.

Future Proof with Interoperability

Once an initial deployment of AMRs is successful and starts to scale, leading logistics companies will look for other tasks that can be automated to continue driving operational efficiency. Selecting the best fit for each task, whether it’s goods-to-person, moving pallets and non-conveyables, depalletizing or picking, often leads to buying different robots from different vendors.

InOrbit is the leader in AMR interoperability, with award-winning InOrbit Connect the only program of its kind for robot certification. IOWA leverages InOrbit Connect, including support for emerging interoperability standards such as VDA-5050, Open-RMF and MassRobotics AMR Interop, as well as integrations with proprietary fleet management software from robot vendors like Mobile Industrial Robots, Omron and OTTO Motors.

InOrbit Warehouse Automation gives logistics operators the power to orchestrate the flow of goods through the latest advances in RobOps.

Ready to launch your facility into the future?

Contact us today to get started