Logistics + InOrbit

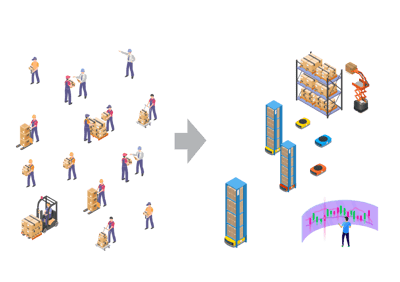

Maintaining effective logistics and keeping the supply chain moving are more critical than ever. Changing consumer habits are shifting demand across different channels. The explosive growth of e-commerce due to ongoing trends and the recent COVID-19 pandemic are challenging in-house logistics operators and third-party logistics providers to grow capacity and drive efficiency while operating on thin margins. Key areas of focus include:

Productivity — driving costs down and improving margins.

Resilience — responding to changing market conditions.

Labor — availability, cost, health and churn.

Forward-thinking operators are turning to advanced automation for repetitive tasks, such as material handling and order-fulfillment. A traditional fixed infrastructure, such as conveyor belts and other machinery, requires a significant upfront investment and tends to be inflexible. Instead, we are now seeing rapid adoption of Autonomous Mobile Robots (AMRs). These are available from many vendors, and come in several shapes and functions — from small tote carts to pallet stackers and tuggers with payloads up to 15,000 lbs.

But with any technology, this creates its own set of challenges. While AMRs are increasingly flexible, they still encounter situations that a robot's on-board software can't resolve on its own. In addition, computer vision and other algorithms occasionally produce false positives. Lastly, the flow of goods within a warehouse or distribution center is constantly changing, which requires a flexible and adaptable solution.

Keeping tabs on robots

InOrbit can help warehouse operators relying on AMRs to keep tabs on the robots and empower employees — whether they are across the warehouse or in a remote operations center — to take actions that keep operations flowing smoothly.

Our RobOps platform can acquire, analyze and process massive amounts of operational data to understand how robots are performing; notify the right people in real-time and respond to incidents as they occur; and enable continuous improvements to the robot software in order to drive operational metrics.

Working with InOrbit, we can give your operation:

- Consistent access to heterogeneous robot fleets;

- Fleet-wide performance visibility and analytics;

- Efficient remote and on-site incident resolution;

- Collaboration between human associates and machines;

- Improved metrics, including mean-time to resolution (MTTR), total cost of ownership (TCO) and service-level agreements (SLAs);

- A dedicated customer success team.