Exploring missions with John Simmons

When dealing with robotics, missions mean much more than just a series of tasks strung together. For operators and those managing robots in the field, a mission is a floor that's been cleaned, an aisle that's been scanned, or an item that's been picked. Mission performance is critical to understanding success

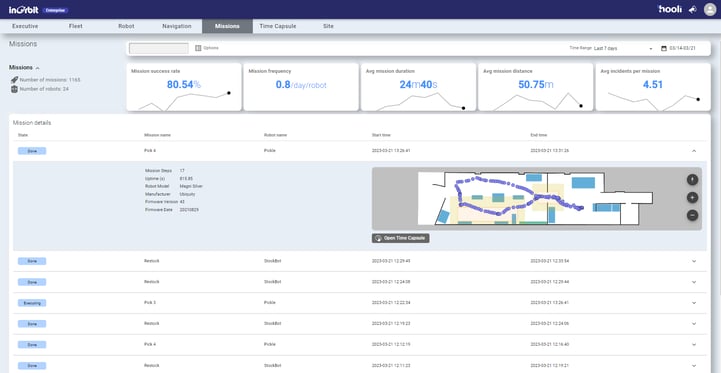

At InOrbit, we recently expanded our missions capabilities, making them more accessible to InOrbit users. This gives our users comprehensive data analytics, enhanced robot fleet observability and easier insights into optimizations for effective end-to-end mission management. Visualized through a new customizable missions dashboard our goal was to give managers and operators easier access to the KPIs that matter most to them and a complete picture of their robot fleet’s ongoing performance. Today we take an opportunity to dive deeper into the role of missions in real-world robot deployments with InOrbit’s Head of Product John Simmons.

John is an accomplished operations and product leader with extensive experience deploying and managing technology at scale, including work as the Director of Operations at Bossa Nova Robotics. John is now applying the lessons he learned in deployment, scalability, and operational efficiency to effective RobOps solutions. As InOrbit’s Head of Product, John leads the advancement of InOrbit’s platform leveraging his extensive experience with autonomous mobile robots (AMRs) in the real world. We were grateful to have had an opportunity to share his insights.

John is an accomplished operations and product leader with extensive experience deploying and managing technology at scale, including work as the Director of Operations at Bossa Nova Robotics. John is now applying the lessons he learned in deployment, scalability, and operational efficiency to effective RobOps solutions. As InOrbit’s Head of Product, John leads the advancement of InOrbit’s platform leveraging his extensive experience with autonomous mobile robots (AMRs) in the real world. We were grateful to have had an opportunity to share his insights.

To start, why are missions important to robot operations?

Our customers don’t buy robots because robots are cool. Our customers buy robots because they need to make something operate more efficiently. A core RobOps principle says that measuring what you’re doing and improving through iteration is how you drive greater efficiency. Mission tracking is a measure of the success or failure for a complete set of work that's been given to a robot. Missions give our customers insights into the performance of their robotic fleets that they need in order to uncover ways to improve their operational efficiency.

What makes this different?

When I was at Bossa Nova, I needed numbers like this regularly (see image). This shows the success rate of robots that I may be managing. But to do something like this: to filter down to a subset of robots and then update by my KPIs… Well, that used to require that I write a series of database queries, come up with the right query to get at the information I needed, then execute it, and manage all of the data and all of those calculations. Even then, data like that would’ve been given back as text that I’d then need to put into a spreadsheet and make into charts or tables that could hopefully drive insights. With InOrbit, it's all done instantly.

When I was at Bossa Nova, I needed numbers like this regularly (see image). This shows the success rate of robots that I may be managing. But to do something like this: to filter down to a subset of robots and then update by my KPIs… Well, that used to require that I write a series of database queries, come up with the right query to get at the information I needed, then execute it, and manage all of the data and all of those calculations. Even then, data like that would’ve been given back as text that I’d then need to put into a spreadsheet and make into charts or tables that could hopefully drive insights. With InOrbit, it's all done instantly.

What sets these visualizations apart from a dashboard in a WMS or other robot software?

Our ability to bring any robot's missions (regardless of the vendor) into one format and show them side by side is key. If you have a MiR and an OTTO in your warehouse. you simply can’t use MiR Fleet to look at your OTTO. InOrbit allows you to bring in many different types of robots - visualizing their status and health, their tasks, and their overall performance. All through one pane of glass.

We also integrate with other systems and fixed infrastructure. That means we have the unique ability to bring select data from warehouse management systems, enterprise resource planning systems, and other information, from say cameras or doors in a facility, into our software.

How do missions play into fleet optimization?

In my previous work with grocery, we had a few missions that our robot would go on in a given day. Grocery aisle 'even' and 'odd'. Between these two missions, we ran inventory scans that covered all of the aisles in a store. So the type of question I regularly found myself asking was: if we’ve now pushed out some new software to say 20% of the robots, how did that affect their completion percentage? Was it better with the new software as compared to the 80% that still had the old software? or worse? Those types of questions are all about mission performance. With InOrbit mission tracking our customers can get those types of insights directly from our platform. These are the insights that drive testing and quick effective optimization.

Can you talk about how missions work with InOrbit’s Time Capsule?

Sure, missions are pre-populated with time bounding in our Time Capsule feature. This is incredibly helpful because it allows users to use Missions alongside Fleet as their highest-level dashboard. From there an operator can easily see if they need to dive in and investigate any autonomy incident in more detail. With one click they can jump directly into Time Capsule for all of the rich information about the surrounding context and data of a mission. It’s such an easy way to get directly to the rich value that Time Capsule can deliver for a time period that you know is measurable. Because an operator knows exactly what the impact is when a mission doesn’t finish.

What was most important when developing missions?

Missions make everything so much easier when it comes to data management. There are great analytics tools out there. There are business intelligence tools that are extremely powerful. We’re not trying to compete with those tools.

If you talk to most operations teams out there, they’re not using those business intelligence tools because they’re extremely hard to use. You need to have a Data Scientist to get the most value from those tools. What are Ops teams actually doing? They're mostly still dumping data into spreadsheets. They’re building Excel tables, that's just what they do. And it's so painful.

Our goal is to give the people actually operating robots real feedback on what’s working and what’s not, that’s easy to get to. So we’ve prioritized the ease of use, for mission tracking. Ease of use to uncover insights; that's the most important thing to us. Our team did a really great job making those insights really accessible. For example, you can filter our widgets by customer, and location and your KPIs are right there already broken out for you. You can see what problems are at hand immediately, It's really tangible and easy to get to value.

—-

Thanks to John for taking the time to explore missions, and sharing his insights into the development process and the issues InOrbit hopes to address with our product.

Feel free to reach out for more information about our RobOps solutions.

* Please note, this interview has been lightly edited for length and clarity.